Hull (-abaloo)

Posted By Russ Emerson on April 7, 2010 at 6:27 pm

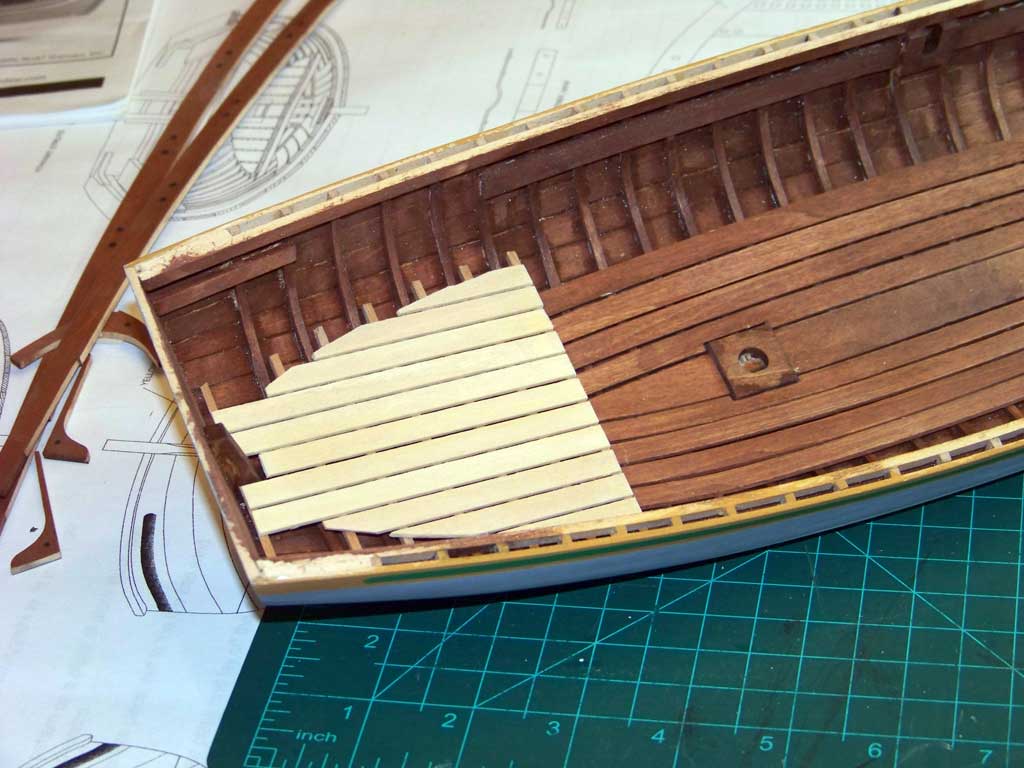

After getting the initial framing and the planking done, and the shell of the hull removed from the construction jig, the next steps involve fitting out the hull interior.

The frames completed so far are not all the frames needed — just enough to hold the hull together for the remaining framing. More frames were bent as before and fitted in between the existing frames. Also, the “cant frames” at the bow were added. The tricky thing here is that the frames are not only curved, but twisted as well, to fit snugly against the interior of the planking.

On the whole, the framing went quite well; I got it all done in one day, with a minimum of breakage along the way.

The “sheer clamps” run along the inside of the frames at the top edge of the hull, making a kind of sandwich holding the frames in place; they were installed next, first being soaked and bent and then carefully cut to fit against the transom. After the glue holding them in place had cured, the tops of the frames were cut down almost flush with the top of the sheer planks/clamps, and then sanded flush to make a good gluing surface for … well, we’ll get to that in a minute or three.

Also installed at this point were the “thwart risers” — the beams on which the thwarts will eventually rest.

[Click to embiggen]

The mast steps — the blocks in which the heels of the masts will be seated — were then installed, with care taken to ensure that they were placed properly so that later, the masts will be properly (i.e., vertically) aligned.

If I’d been clever enough to have thought of it beforehand, I would have stained the insides of the planks before gluing them to the frames earlier. I am not, however, that clever, so the interior of the hull was stained at this point. I am not at all happy with how it came out — it’s too uneven and blotchy, due in no small part to the difficulty of removing excess stain from between the frames.

OK, lesson learned: stain first wherever possible.

The floorboards were next stained and installed. They had to be soaked and bent first; even so, they were reluctant to fit properly. This is (so far) the only place on the model where I’ve used cyanoacrylate glue; everywhere else, I’ve used ordinary wood glue.

At this point, the kit stand was assembled and stained.

[Click to embiggen]

With the inside of the hull stained, this seemed the right time to paint the exterior; indeed, the kit manual suggests so. I primed the outside and sanded it, filling any major gaps discovered along the way with wood putty. After sanding, a second coat of primer was applied, and the final sanding done.

The general color scheme is: off-white below the waterline, grey above, with a yellow/ochre stripe at the sheer, with a decorative green stripe inset on the yellow/ochre.

I painted the off-white and the yellow/ochre at the bottom and top of the hull and let them dry. Next, I took measurements off the plans and marked the waterline.

[Click to embiggen]

The waterline was carefully masked off, as was the yellow/ochre strip at the top of the hull, and grey paint applied between them. Two coats were all that were required for each color. The green stripe was added last.

[Click to embiggen]

At this point, I discovered the only major flaw I have found thus far in the kit.

While examining the plans and the photos in the manual, I realized that the quarterdeck ought to have been dealt with somewhere along the line. However, there isn’t a single word in the manual about it. Not one word.

Fortunately, the plans are fairly clear, and I was able to fabricate the quarterdeck from scratch. Because the quarterdeck slopes and has to fit inside the curve of the hull and around the stern post, a fair amount of trial-and-error fitting and trimming was required.

Once I was satisfied with the fit, the quarterdeck assembly was stained and installed as a unit.

[Click to embiggen]

The parts comprising the gunwales were stained and assembled over the plans, cellophane being used to keep from gluing the parts to the plan sheet. Also shown here are the thwarts, the bow grate and the rudder, though these won’t be installed quite yet.

[Click to embiggen]

The bow ends of the gunwales were rather fragile, because as they curve towards the stem, they gets into a bit of a cross-grain situation where the wood is weak. In fact, I accidentally snapped the blasted things twice. Before the glue-up, I reinforced the weak spots with masking tape, which I thought (correctly, it turned out) would be enough to hold the weak spots safely while the glue cured.

Because of the bending involved, I pre-drilled holes at a few key spots for pins to hold things in place during the glue-up.

Glue was then applied to the top edges of the sheer planks and sheer clamps, and the gunwales pinned and clamped in place and left overnight for the glue to cure. The next day, I pulled the pins and filled the holes with tiny bits of stained putty.

[Click to embiggen]

The hull — and the kit as a whole — is nearly complete.

Comments