Mayflower: the Frame

Posted By Russ Emerson on October 11, 2011 at 9:00 am

As promised last week, cats notwithstanding, I have here a few details of the Mamoli Mayflower project to date.

Construction of the hull began with me having to shoo away one or another of the cats (usually Kismet, the stinker) while I prepared the 5mm plywood keel and bulkheads for assembly.

Construction of the hull began with me having to shoo away one or another of the cats (usually Kismet, the stinker) while I prepared the 5mm plywood keel and bulkheads for assembly.

The keel was rather significantly warped, so soaking followed by steaming with a clothes iron was the order of the day. No amount of such treatment was sufficient, however, to completely remove all of the bend from the wood, but I managed to get it fairly straight. If I were looking to make a museum-piece, I’d have taken the time to cut a new keel myself.

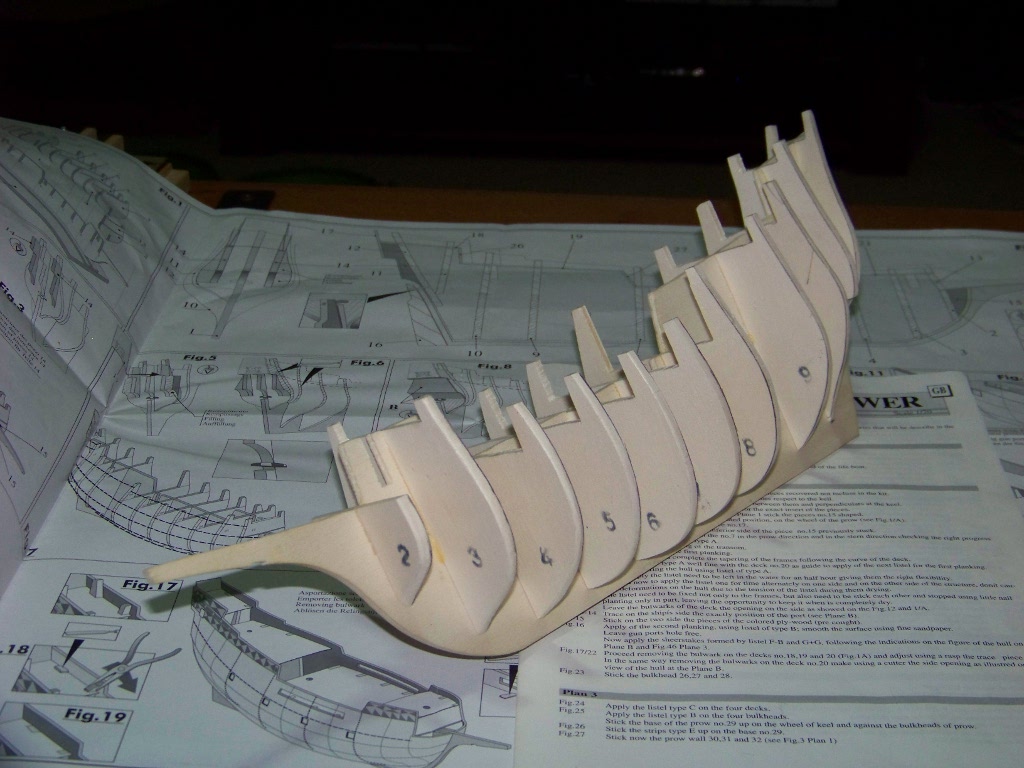

The bulkheads require beveling for the planking which is to come. I gave each a rough bevel before assembly; I marked one edge of each bulkhead with a pencil to ensure that I didn’t go just a bit too far when removing material.

The bulkheads require beveling for the planking which is to come. I gave each a rough bevel before assembly; I marked one edge of each bulkhead with a pencil to ensure that I didn’t go just a bit too far when removing material.

Fine-tuning the bevel will happen after the frame is assembled.

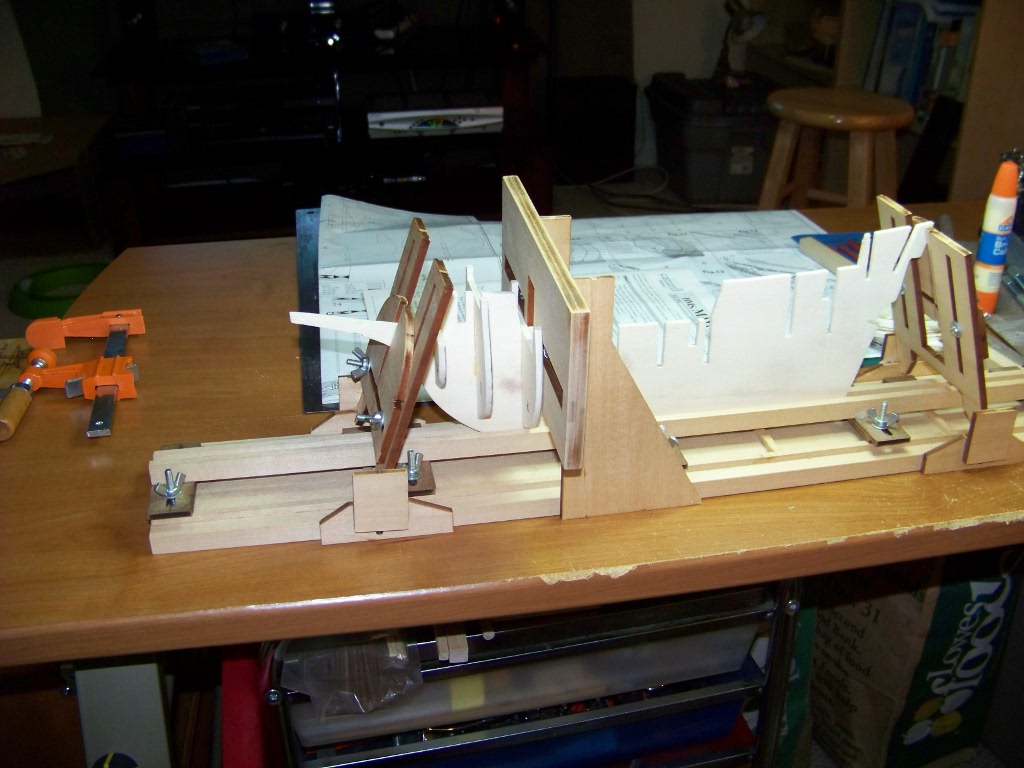

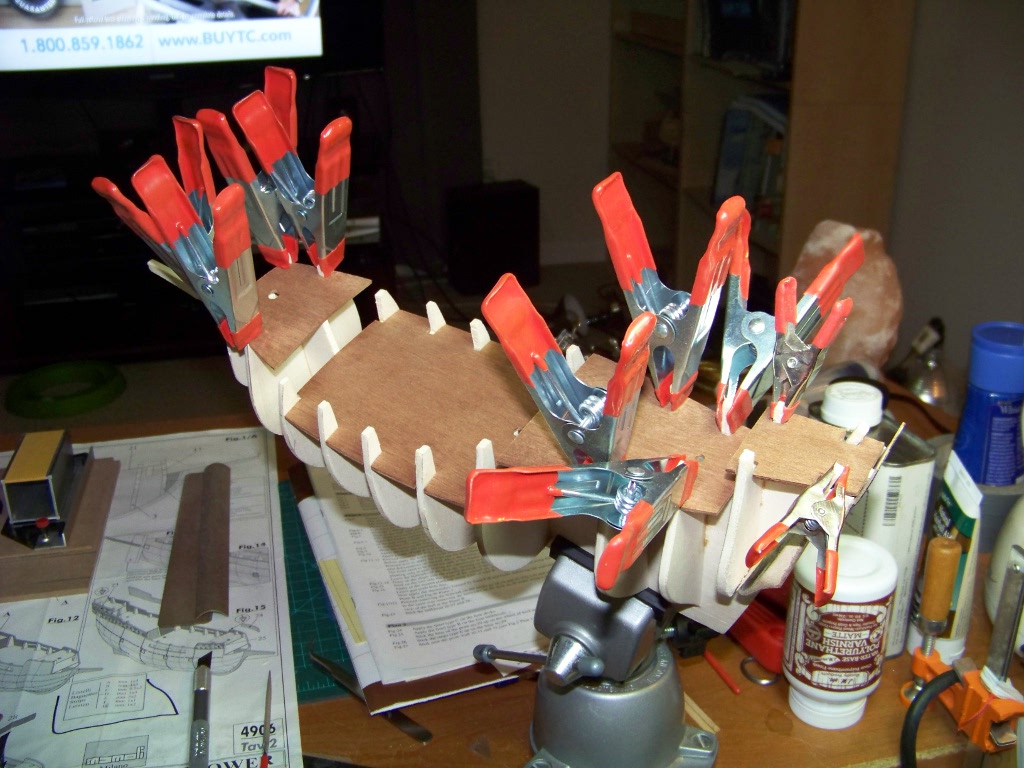

The actual assembly was aided by the use of a “Fair-a-Frame” which I had acquired from Model Expo. Mounting the keel section on the base held it straight, and as the bulkheads were glued and added one by one, they were held square to the keel while the glue dried.

The actual assembly was aided by the use of a “Fair-a-Frame” which I had acquired from Model Expo. Mounting the keel section on the base held it straight, and as the bulkheads were glued and added one by one, they were held square to the keel while the glue dried.

I’m willing to swear in a court of law that there’s a tool or jig out there for darn near every possible part of putting one of these things together.

Here we see the frame with all the bulkheads added. I know, I know, it looks spectacular, but we’re not done with the frame yet, oh no.

Here we see the frame with all the bulkheads added. I know, I know, it looks spectacular, but we’re not done with the frame yet, oh no.

I don’t have a relevant photo at this stage, but bow blocks had to be added; they will be used later as anchor points for the planking which will follow in the not too distant future.

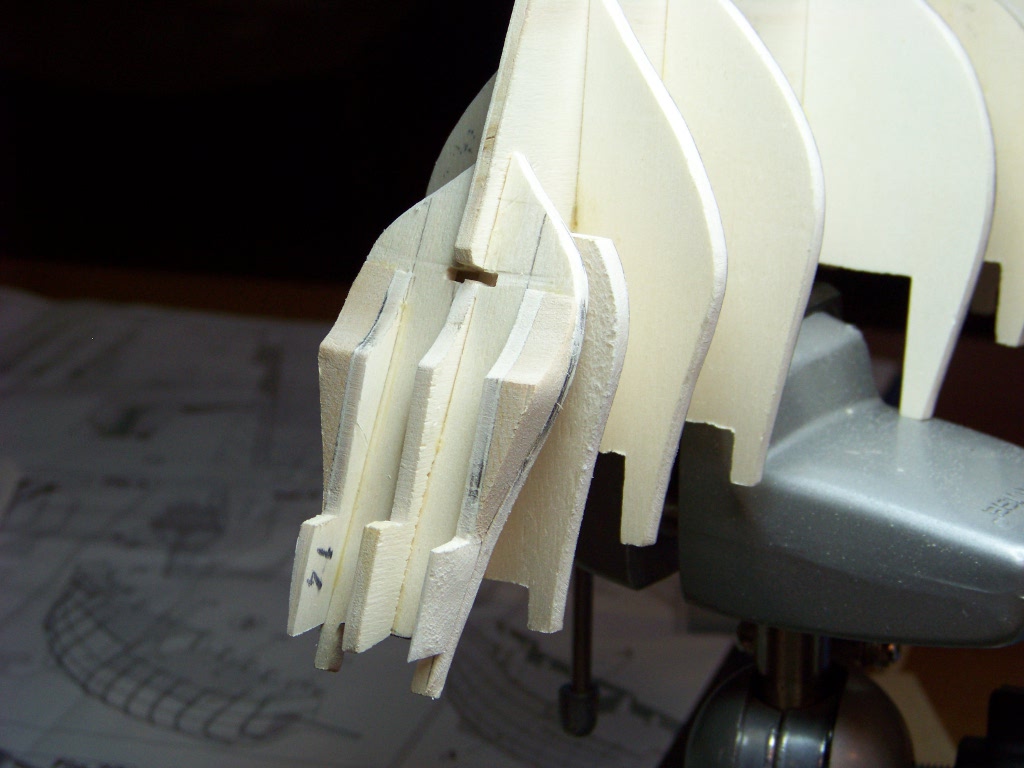

Here we see that the stern timbers have already been added; pencil marks taken right off the plan were used to good effect. Filler blocks were added outboard.

Here we see that the stern timbers have already been added; pencil marks taken right off the plan were used to good effect. Filler blocks were added outboard.

I’ll note here that a well-drawn plan is, in my experience so far, a rarity. They never seem to match up 100% with the parts in hand, so sometimes some informed guesswork is needed. This makes it even more important to be thoroughly familiar with the plans and instructions before construction begins.

Even (or perhaps especially) if, as in the case of this model, the instructions are very poorly translated from Italian to English.

And here we see the filler blocks after shaping.

And here we see the filler blocks after shaping.

At a later date, planking will end up being secured to those blocks, so yeah, they’re kind of important. So important, in fact, that the kit doesn’t include material for them; instead, the builder is advised to “Fill, using recovered wood, the inferior side of the piece no.15 previously stuck.”

Which I took to mean, “use scrap wood to fill the space outboard of parts number 14.”

Yeah. The instructions got the part numbers wrong. Fortunately they were correct on the plan sheets.

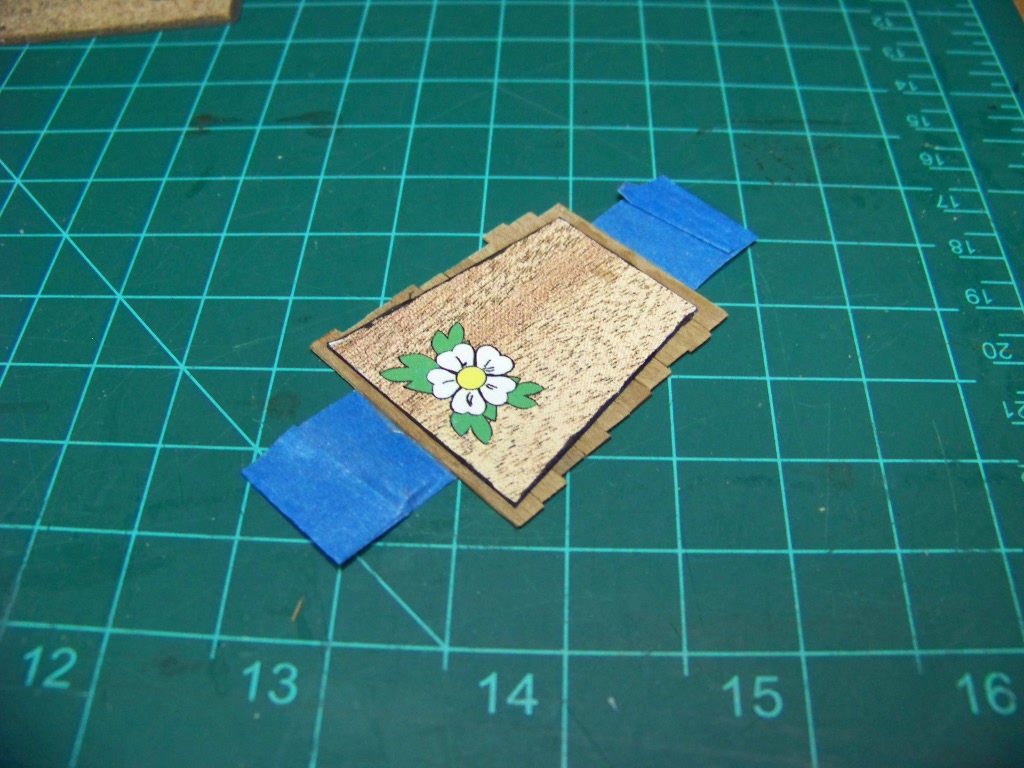

One aspect of this kit that I haven’t seen elsewhere is the use of pre-printed (on thin cardboard) graphics to represent portions of the ship that were painted in the fairly bright colors and patterns of the Jacobean era.

One aspect of this kit that I haven’t seen elsewhere is the use of pre-printed (on thin cardboard) graphics to represent portions of the ship that were painted in the fairly bright colors and patterns of the Jacobean era.

To prepare the transom (the stern piece), I cut it out with the sharpest blade in my inventory, and then used a sharpie to mark the white edges of the cuts. Unfortunately, the ink bled just a bit into the cardboard; I’m not sure how to get around that in the future.

I cut a strip of walnut into a number of pieces, which I edge-glued together with the help of some tape. Once that glue had dried, I sanded the walnut smooth and then glued on the cardboard cutout.

While the stern panel was drying, I took a look at the assembled frame, and noted that a couple of the bulkheads were undersized. One was only 1mm off; the other was 2mm.

While the stern panel was drying, I took a look at the assembled frame, and noted that a couple of the bulkheads were undersized. One was only 1mm off; the other was 2mm.

If left this way, the exterior planking would either not make any contact with those bulkheads, or would have to make a dip in the shell of the hull in order to make contact.

Even with so small a “miss,” neither option was desirable, so I padded out the bulkheads in question with spare strips of wood.

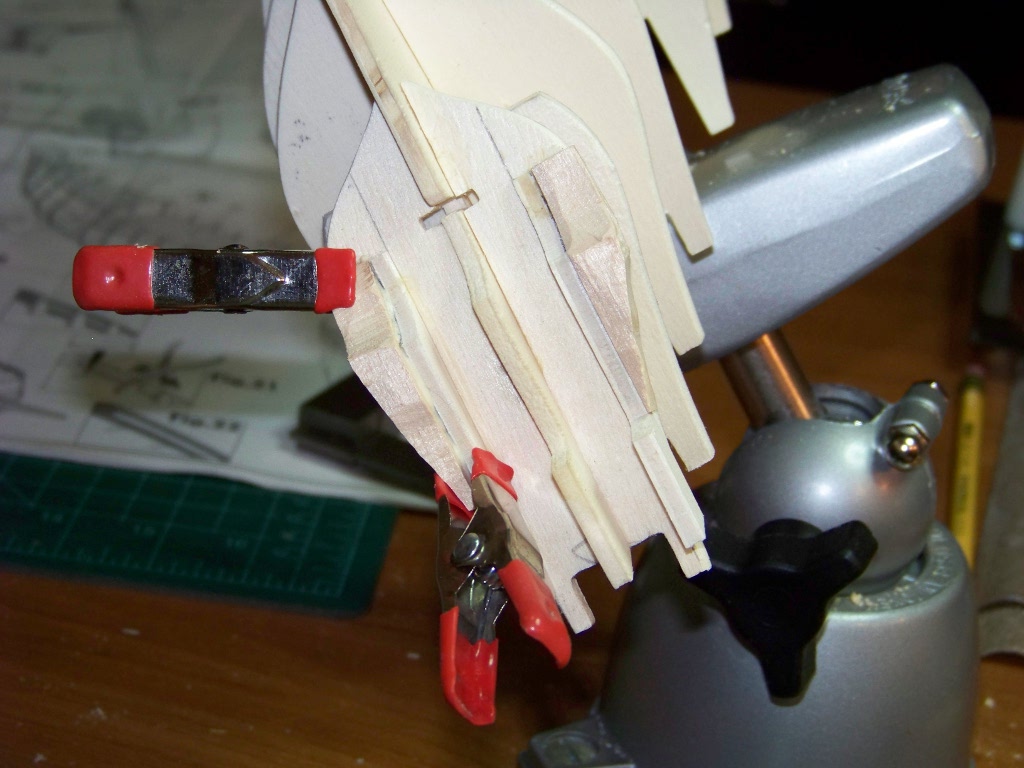

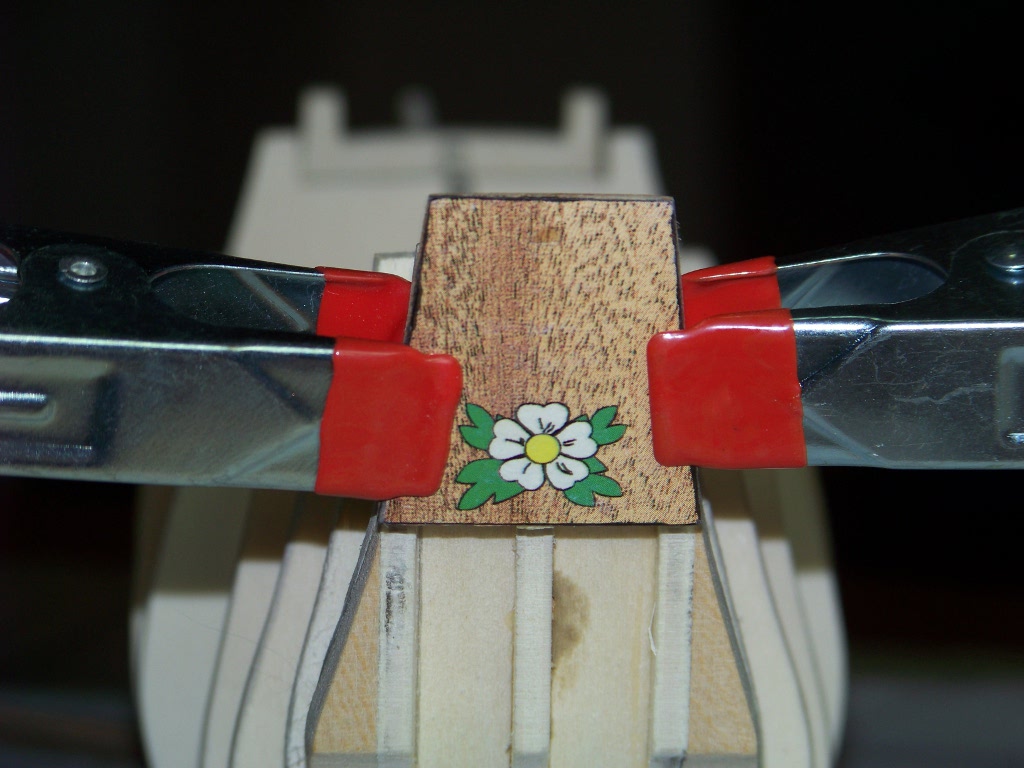

At this point the transom was affixed to the stern timbers. A bit of glue and some clamping did the trick.

At this point the transom was affixed to the stern timbers. A bit of glue and some clamping did the trick.

So far I’ve used only Elmer’s wood glue, no superglues or epoxies. We’ll see if that changes.

Oh, and: I haven’t used any power tools thus far on the project. I didn’t make a big deal about it, but I didn’t use any power tools on my previous project, the Bounty’s launch, either.

That will definitely be changing in the future.

Before the main planking begins, the stern has to be planked; when completed, the main planking should lap over the ends of the stern planks so that the end grain of the main planks will be visible.

Before the main planking begins, the stern has to be planked; when completed, the main planking should lap over the ends of the stern planks so that the end grain of the main planks will be visible.

Unlike the main planking, which will be done in two layers, the stern only requires the walnut finish layer.

Here’s a look at the completed stern planking.

Here’s a look at the completed stern planking.

It’s been trimmed to its final profile, but I won’t be sanding it completely smooth until the rest of the ship’s planking is complete and ready to be sanded.

With the stern complete, the only assembly remaining to be done before the planking process begins is the installation of the decks.

With the stern complete, the only assembly remaining to be done before the planking process begins is the installation of the decks.

Glue was applied and each deck dropped in place over the bulkhead “ears” and clamped; a minimum of trimming and fitting was required to get each deck in place. I was actually pretty pleased with how well that went.

Comments